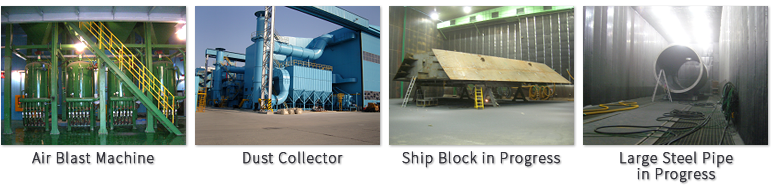

AIR BLAST MACHINE

- Shot balls are blasted onto the surface of steel structure by using high-pressure compressed air.

It is a facility to remove the scale or coating on the product’s surface within the room.

Mostly used at huge structures such as ship blocks and containers.

- Application : Ship blocks, Large steel structures, Railway vehicles and Containers

Specification

| ROOM SIZE(M) |

6 (W) x 10 (L) x 5 (H) |

10 (W) x 20 (L) x 10 (H) |

30 (W) x 30 (L) x 15 (H) |

50 (W) x 50 (L) x 20 (H) |

| Application |

Steel Structure |

Steel Structure |

Ship Block – Interior Part |

Ship Block |

Air Blast Unit

(Projection Device) |

2N/1T 2 = 4N |

3N/1T x 2 = 6N |

6N/1T x 2 = 12N |

6N/1T x 2 = 24N |

| Tank Capacity |

40~80 ton |

100~150 ton |

200~300 ton |

500~600 ton |

SHOT Recovery

(S/C, B/E, D/S) |

30~80 ton |

100 ton |

150~200 ton |

200~300 ton |

Shot Recovery

Mothod |

Serial Recovery or

Input

HOPPER + BELT

CON’V

or SCREW CON’V |

Input (with Equipment)

HOPPER + BELT CON’V

or SCREW CON’V

|

Input (with

Equipment)

HOPPER + SCREW CON’V

|

Input (with

Equipment)

HOPPER+ SCREW CON’V

|

Vacuum

Recovery |

OPTION |

OPTION |

50CMM x 100HP

(Required quantity) |

50CMM x 100HP

(Required quantity) |

| Dust Collector |

300~1,000 ㎥/min |

2,000~3,000 ㎥/min per Machine |

5,500 ㎥/min per Machine |

6,000 ㎥/min per Machine |

Above application is just an example.

Please consult us for the detailed specifications according to your materials and work conditions.

- Relevant photo-cuts